Bill and Debbie Hamrick

I

Integrity Machining Inc.

Precision with Purpose. Excellence with Integrity.

We are grateful for the opportunity to earn your trust and be considered as your machining partner. Our mission goes beyond parts, we aim to serve people. Every cut, every tolerance, every delivery is done with care, character, and commitment.

Whether you need support on a prototype, a critical component, or a long-term production run, we’re here to serve with integrity in every sense of the word.

Let’s build something lasting, together.

-

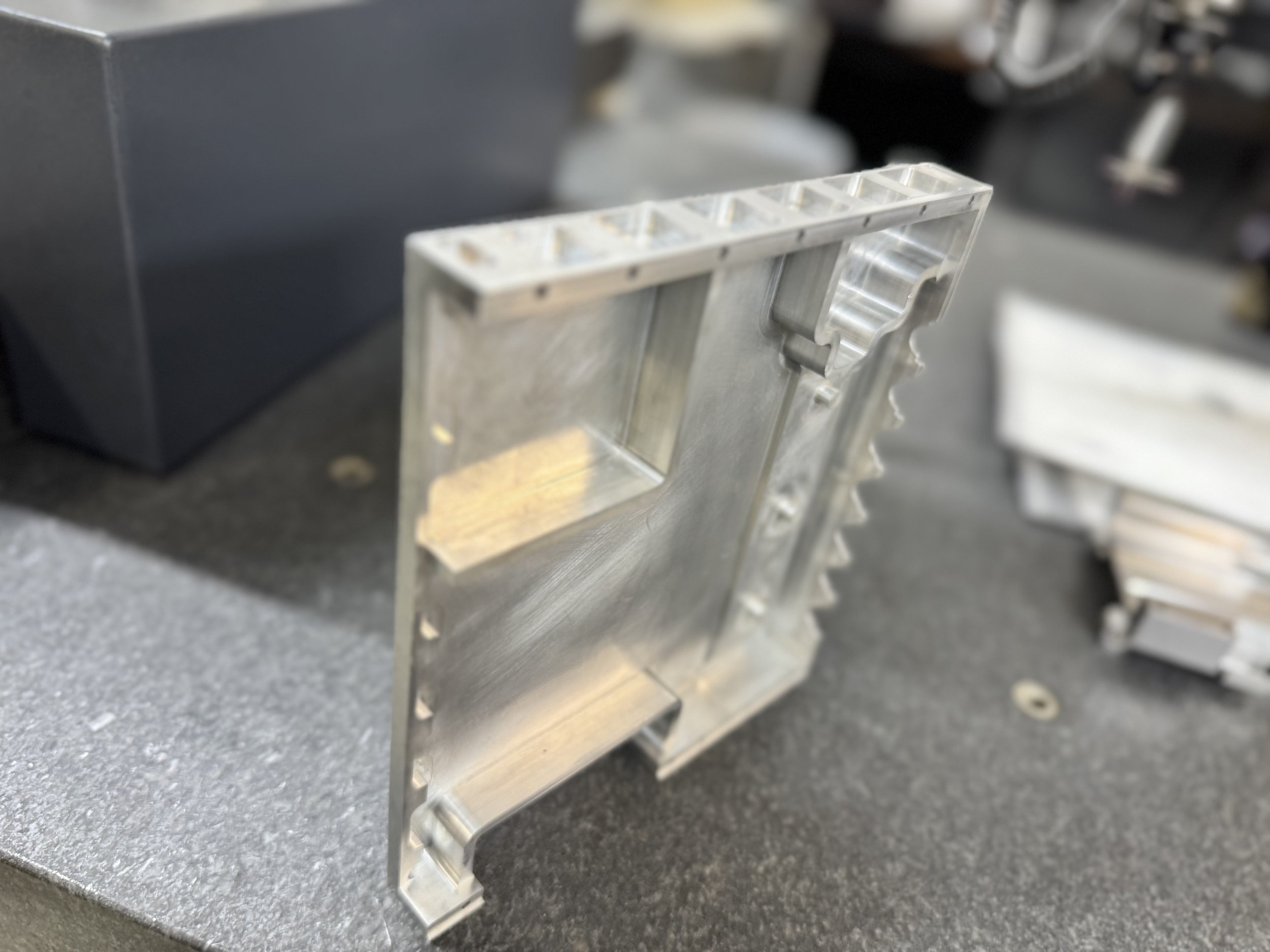

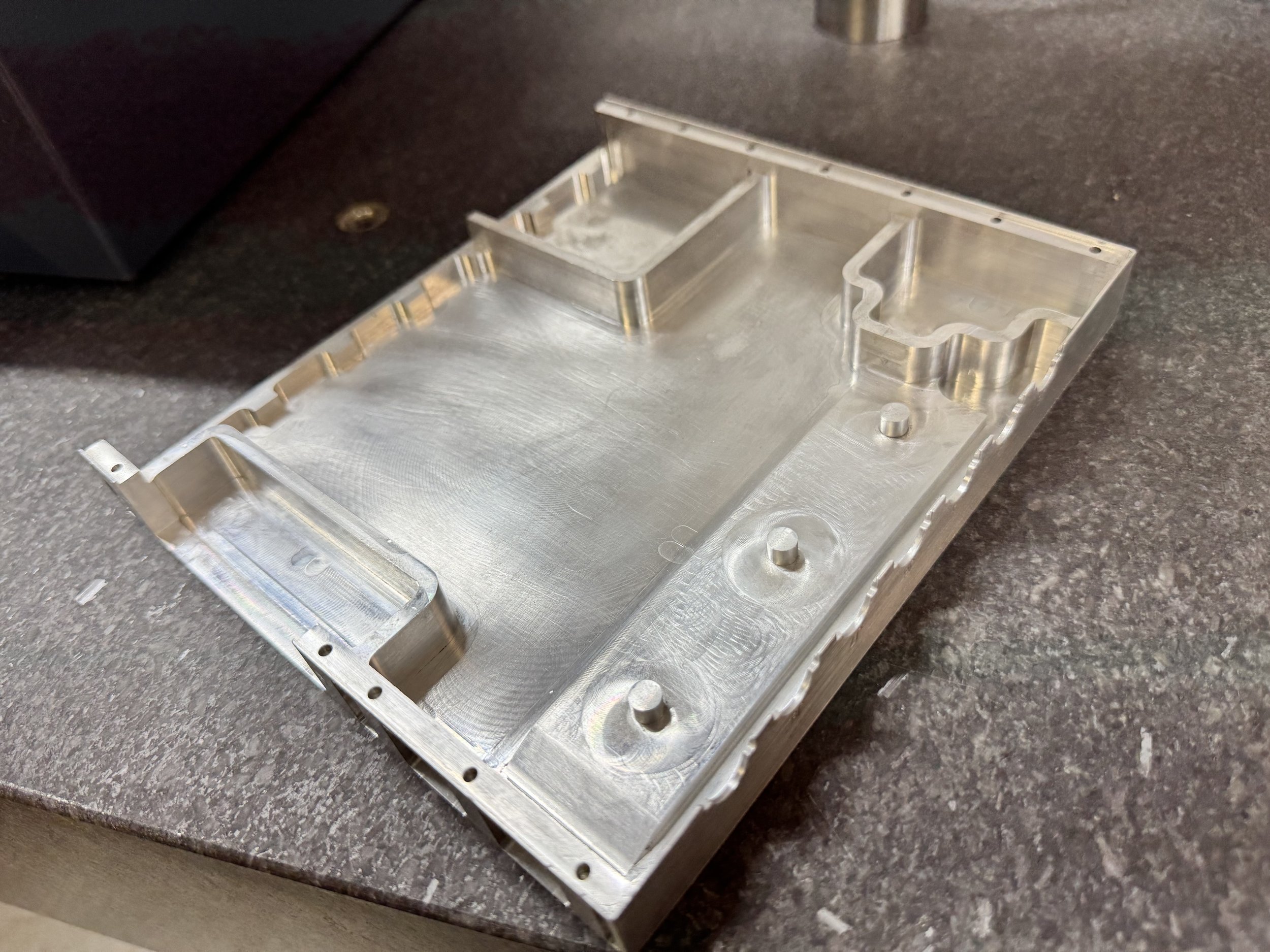

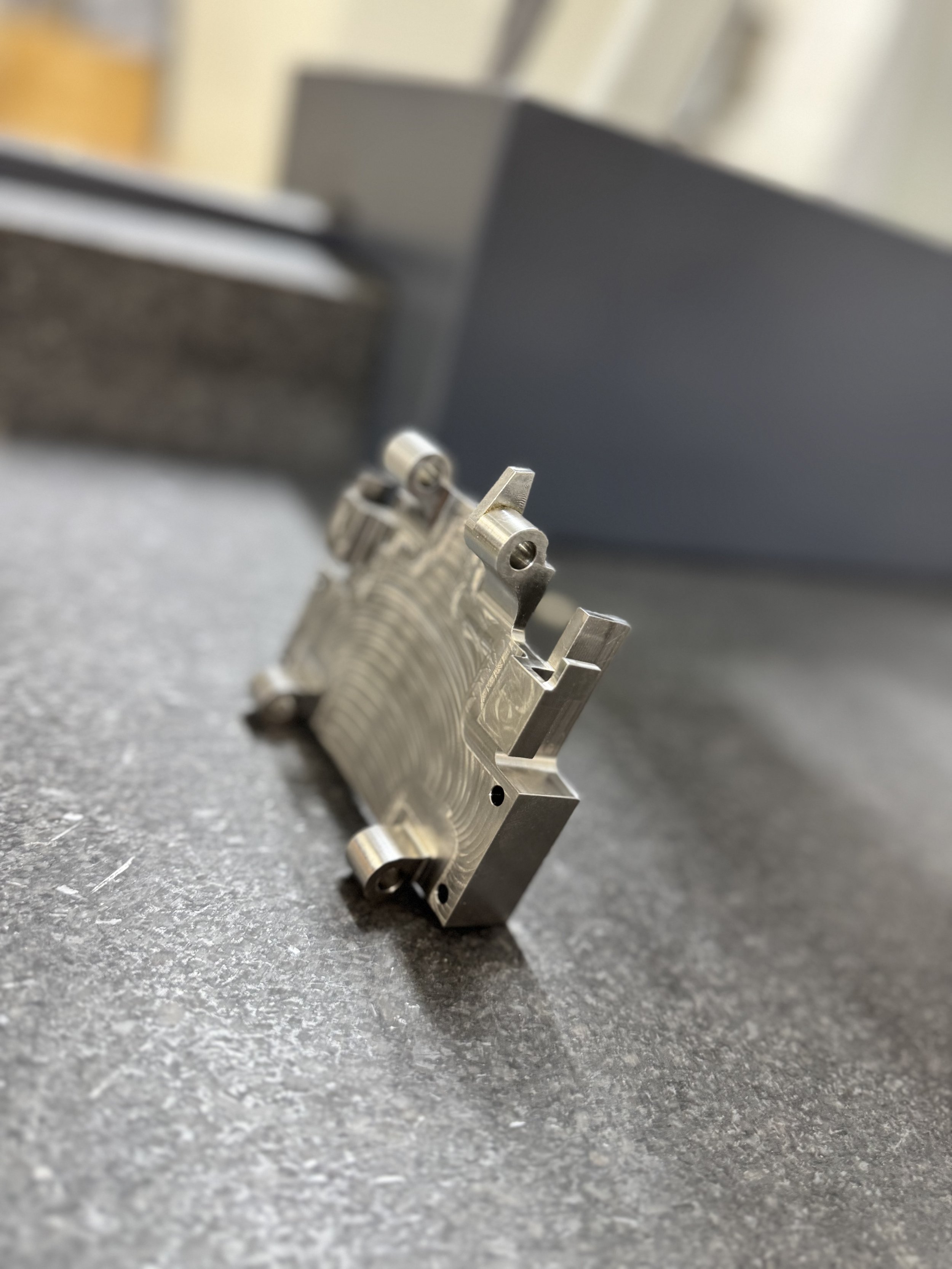

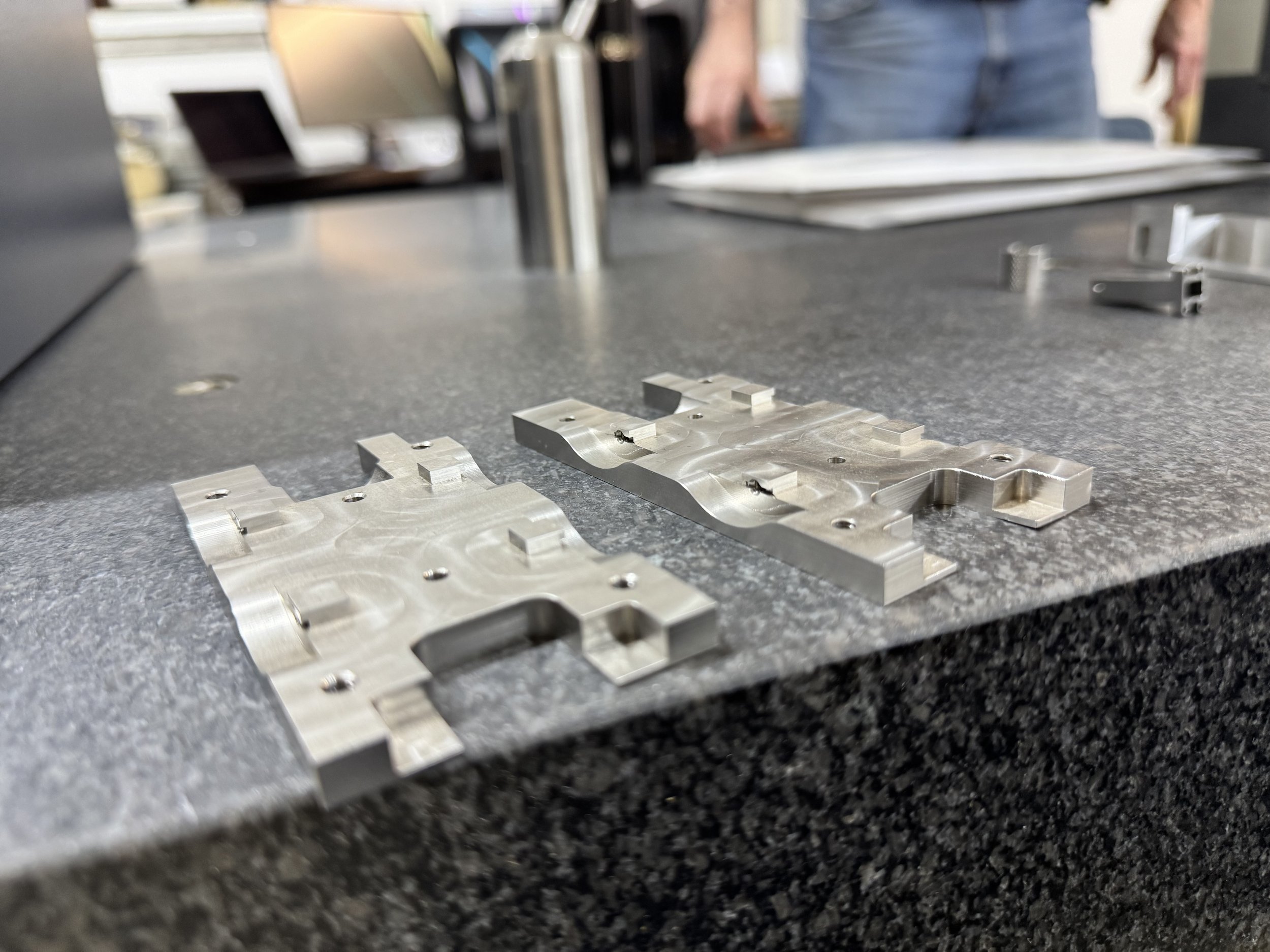

We are a machine shop compliant to AS9100D and ISO 9001:2015, offer 3, 4, and 5-axis machining. Manage lead times, reduce inventory, and enjoy on-time product delivery.

-

Our turning experience across multiple industries allows us to meet any level of complexity/difficulty for a wide range of projects.

-

We consistently hold tolerances of ±.0002". Cleaning, testing, culture, and dedication to continuous improvement make this possible.

-

Our highly-advanced BobCAD software allows us to model/simulate any job or procedure. That means design to finished product FAST.

-

We can meet lead times and budget quickly, efficiently, and economically. Go to market faster, without blowing up your budget.

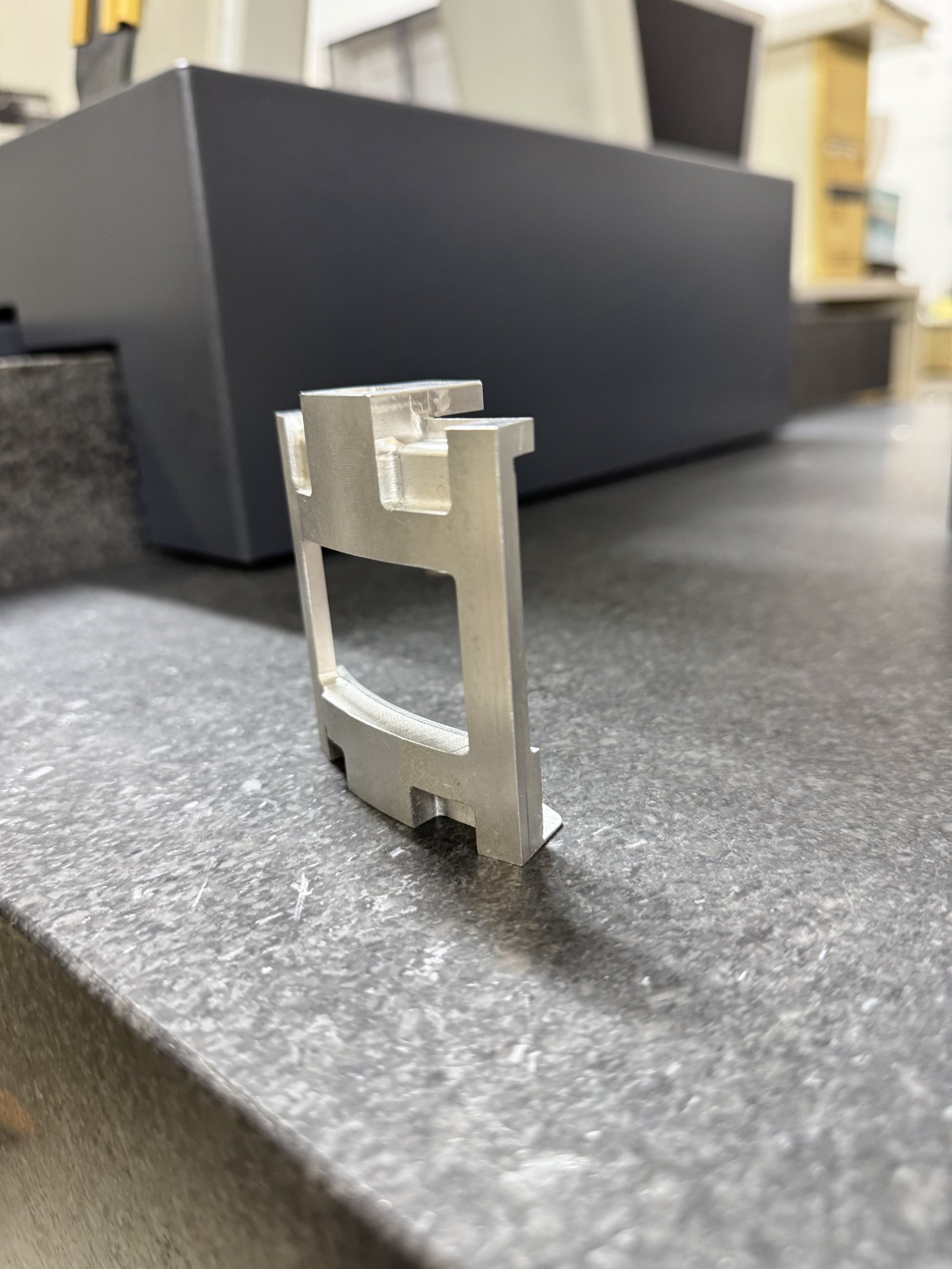

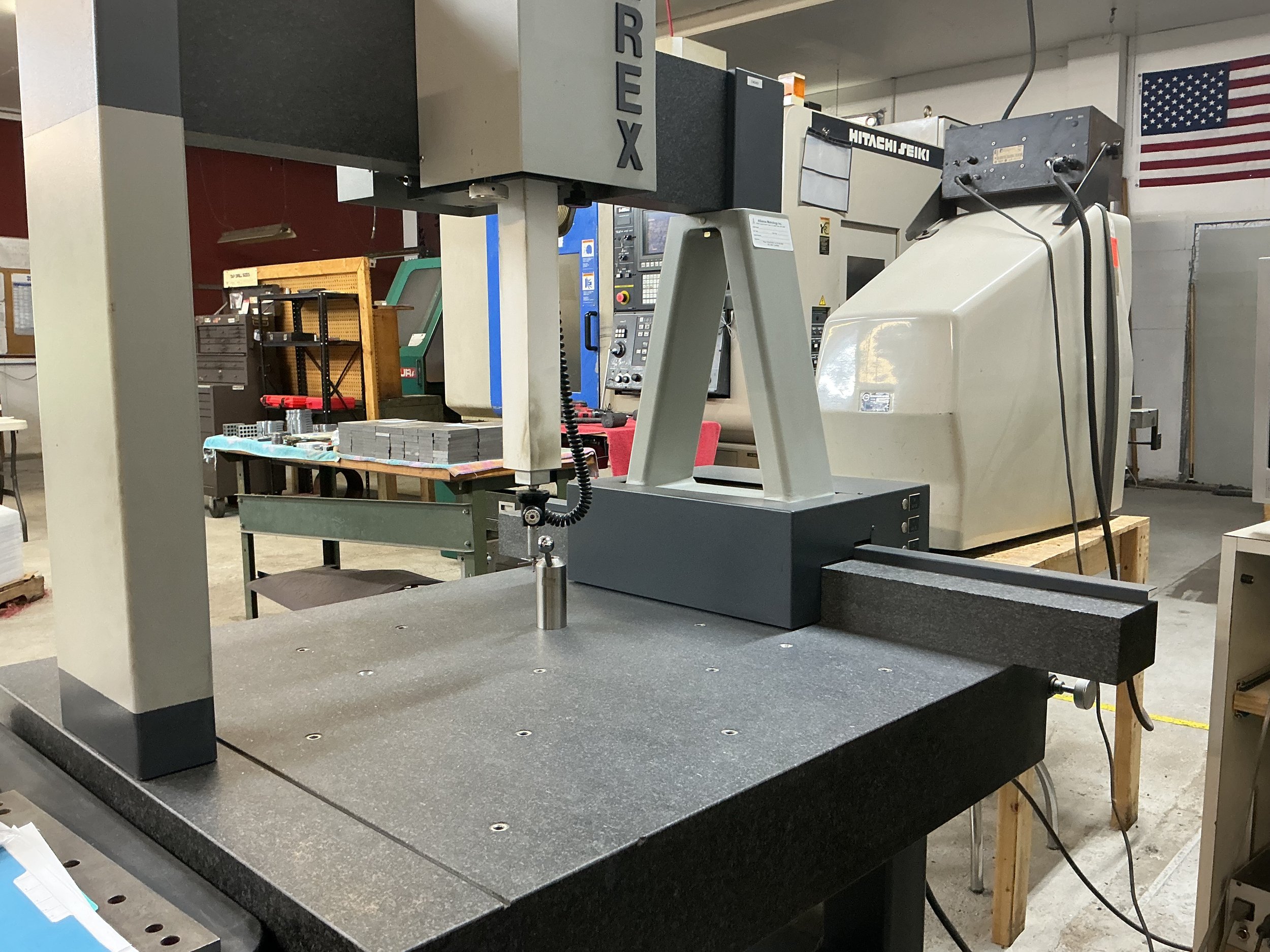

Rex Coordinate Measuring Machine (CMM)

Key Capabilities

Dimensional Inspection of complex machined parts

Tight Tolerance Verification to within ±0.002 mm

Non-contact probing & touch-trigger measurement

Supports GD&T (Geometric Dimensioning and Tolerancing) validation

Ideal for aerospace, medical, defense, and precision machining applications

DMG Mori 70 Evolution

-

Capabilities

True 5-axis machining for complex, contoured surfaces and multi-face operations

Integrated Renishaw probing for automated in-process inspection and tool calibration

Maintains high precision across demanding aerospace, medical, and defense parts

Capable of machining intricate geometries in a single setup — reducing lead time and error

DMG Mori

-

Capabilities

High-speed, high-precision milling

Ideal for aluminum, stainless steel, titanium, plastics, and exotic alloys

Exceptional surface finishes with tight tolerance control

Supports both prototyping and production runs

Hitachi Seiki Mill VM42

-

Capabilities

Ideal for small- to mid-size production runs

High stability and rigidity for machining steel, aluminum, and plastics

Efficient tool changes for reduced cycle time

Supports tight tolerance work across a range of part geometries

Hitachi Seiki Mill VM43

-

Capabilities

Efficient handling of small- to medium-batch machining

Excellent for high-speed aluminum, steel, and plastic component work

Broad tooling capacity reduces cycle time and increases part complexity

Proven reliability and repeatable accuracy in a production environment